How CoolBlue Protects Your Motors and Bearings

CoolBlue Inductive Absorbers protect motors and bearings from high frequency currents caused by Variable Frequency Drives. Without CoolBlue, damaging currents emitted by variable frequency drives can lead to bearing damage and ultimately electric motor failure. Some types of bearing damage include pitting, fluting, frosting of bearings, lubrication break down and overall destruction of the bearing.

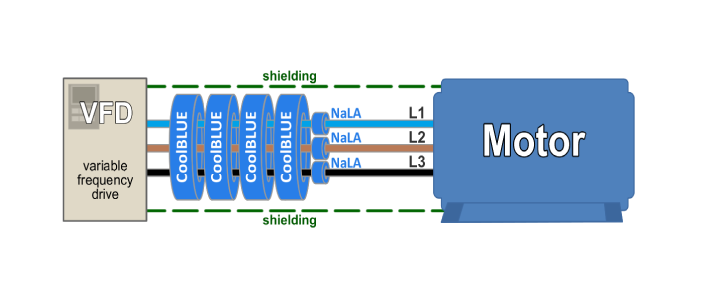

CoolBlue are inductive absorber rings that are installed on all three power phase lead wires between the variable frequency drive and the electric motor. Once installed, CoolBlue acts as a common mode choke that reduces transient voltages, stray capacitive currents and common mode currents before they reach the electric motor.

Installing CoolBlue in your variable frequency drive applications can prevent production downtime, additional maintenance, costly motor repair, and expensive bearing replacement. In addition to the benefits of protecting your bearings and motors, CoolBlue is easy to install, lasts the lifetime of your motor and is maintenance free.

Common applications for CoolBlue include:

- OEM Manufacturers of HVAC Equipment

- Paper/Bottling/Food/Chemical Manufacturing

- Washdown Applications

- Hospital, Office and Commercial Buildings

- Automobile and Related Product Manufacturing

- All Pump and Fan related applications

- Wind, Solar and other renewable energy applications

- All Variable Frequency Drive Applications

How to Select the Correct CoolBLUE products:

See our full blog on our CoolBLUE selection guide here: How to Select the Correct CoolBLUE for your Application

For more specialized motor applications that require higher reliability, Nanoperm Line Absorbers (NaLa) are recommended in addition to CoolBlue Inductive Absorbers. NaLa further reduces the variable frequency drive noise and peak values of current. Unlike CoolBlue, NaLa is installed on each of the power phase wires, not over all three power phases. NaLa is to be used in conjunction with CoolBlue to further increase the reliability and uptime of your motor system.

The CoolBlue and NaLa products are sized by HP and total cable length from the VFD to motor. If there are two cables on each output leg then the distance needs to be multiplied by 2 or so on for each added cable per phase. There are 4 popular sizes that are stocked that cover from 1/4HP to 400HP. When lead lengths are longer then 150ft, 300ft, 450ft, and 900ft, then more cores are added to the system. For more information on how to properly install CoolBlue, see this installation guide.

One major advantage of installing CoolBlue and NaLa is the reduced installation time needed over other options. Also, there is no need for an insulated bearing on motors with over 100 HP. CoolBlue and NaLa are readily available at Dreisilker Electric Motors, Inc.

In addition to the usage of CoolBlue in VFD applications, you can also protect your motors with Aegis Shaft Grounding Rings. The Aegis Rings work by diverting the damaging voltages away from the bearings by sending it to ground through the motor frame. The rings are made of conductive microfibers that encircle the motor shaft and is installed on the drive end of the motor. To learn more about the Aegis rings, read our blog Aegis Shaft Grounding Rings Protect your Motors and Bearings.

To celebrate the launch, Dreisilker held a ribbon cutting ceremony to kick start the new software. The accounting and IT departments were asked to do the honors of cutting the copper (wire) ribbon with President, Leo Dreisilker.

To celebrate the launch, Dreisilker held a ribbon cutting ceremony to kick start the new software. The accounting and IT departments were asked to do the honors of cutting the copper (wire) ribbon with President, Leo Dreisilker.