Vacuum Pump Motor Repair

Complete Vacuum Pump Motor Repair Services

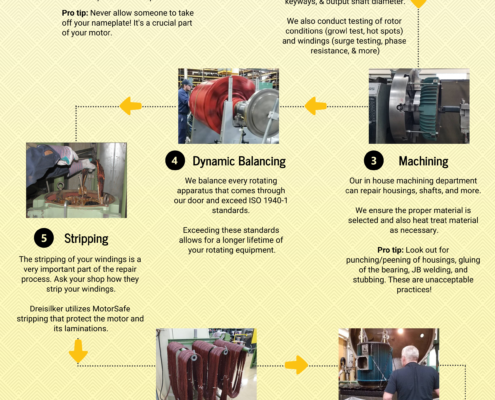

Dreisilker’s MotorSafe Repair method restores vacuum pump motors back to OEM specifications or greater to maximize its reliability.

Our superior repair methods, coupled with our collection of manufacturers’ winding and technical data files, puts us more than one step ahead of the rest.

At Dreisilker, we understand the importance of vacuum pump motors in a variety of applications. That’s why we have invested in the skills and knowledge of our technicians to provide quality repairs that you can rely on. When you entrust your vacuum pump motor to us, you can be confident that it will be repaired to the highest standards. With over 65 years of experience, we have the expertise to get your vacuum pump motor running like new again. Contact us today to learn more about our vacuum pump repair services.

Vacuum Pump Motor Brands We Service:

A Repaired Vacuum Pump Motor