Side Channel Vacuum Blower Repair

Complete Side Channel Vacuum Blower Repair Services

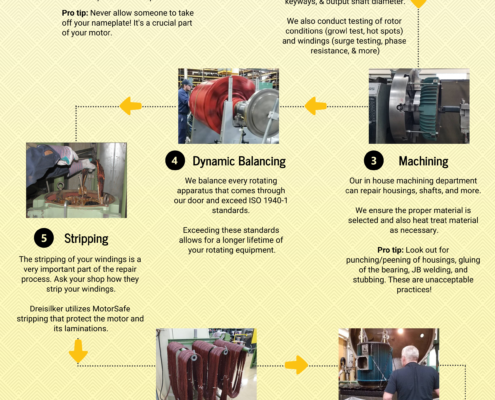

Dreisilker’s MotorSafe Repair method is expertly designed to restore side channel vacuum blower motors back to their original manufacturer specifications or even improve them, significantly enhancing their reliability.

Our exceptional repair techniques, combined with our extensive archive of manufacturers’ winding and technical data files, clearly set us apart in the field of side channel vacuum blower repair. We recognize the critical role these motors play across numerous applications, which is why we’ve heavily invested in the training and development of our technicians. This ensures that we provide repairs of the highest quality that our clients can depend on.

By choosing Dreisilker for your side channel vacuum blower motor repairs, you’re opting for a service backed by over 65 years of expertise and a commitment to excellence. Rest assured, your motor will be repaired to meet the highest standards, ensuring it operates like new. Reach out to us today to find out more about how our repair services can support your operations.

Vacuum Pump Motor Brands We Service:

Testing a Side Channel Vacuum Blower