How-To Wire Condenser Fan Motors Properly in 3-Wire & 4-Wire Configurations

“My original condenser fan motor has three wires and the replacement condenser fan motor that I bought has four wires – did I buy the wrong motor?”

This is by far the most common post-transaction question that we receive from customers that have recently purchased replacement condenser fan motors. Simply put, no – you did not buy the wrong condenser fan motor. While most original condenser fan motors only have three wires, it’s very common for replacement condenser fan motors to have four. This guide will explain how to wire your new condenser fan motor using a four wire setup or a three wire setup when using a single run capacitor or a dual run capacitor.

A review of the components:

If you recall from our residential cooling season guide, outdoor condenser units use a switch called a contactor. This switch is controlled by the thermostat and closes to complete an electrical circuit when electricity needs to be supplied to your condenser fan motor and compressor. Think of the contactor almost as a gatekeeper – two legs of 115 volt electric supply need to flow through it in order for your system to function properly.

Condenser units also use a component called a run capacitor. Run capacitors allow condenser fan motors and compressors to run more efficiently and they’re rated by a unit of measurement called microfarad. Dual run capacitors are used for both your condenser fan motor and your compressor. Single run capacitors are used exclusively for just your condenser fan motor or just your compressor. Like your contactor, your capacitor needs to be wired correctly in order for it to function properly.

Using a dual run capacitor:

If you’re using a dual run capacitor, you’re only going to use three of the four leads coming off the new condenser fan motor.

You’re going to wire the black lead to where the black lead on your previous condenser fan motor was wired to. This will likely be back to your contactor. You’re going to wire the white lead to where the white lead on your previous condenser fan motor was wired to. This will likely be the “C” or “Common” terminal on your dual run capacitor. Finally, you’re going to wire the brown lead to where your previous brown lead was wired to. This will likely be the “F” or “Fan” terminal on your dual run capacitor. The brown lead with the white tracer will not be used for this setup. You can use a wire nut and electrical tape to tie it off.

NOTE: You’ll need a jumper between the “C” or “Common” terminal on the capacitor and one leg of the contactor.

Using a single run capacitor with a four wire setup:

If you purchased a new condenser fan motor with a new single run capacitor, this will be the wiring setup that you’ll be using. You’re going to wire the black lead to where the black lead on your previous condenser fan motor was wired to. This will likely be back to your contactor. You’re going to wire the white lead back to the other leg of your contactor. You’re going to wire the brown lead to one set of terminals on your new capacitor and you’re going to wire the brown lead with the white tracer to the other set of terminals.

Using a single run capacitor with a three wire setup:

If you purchased a new single run capacitor and the condenser fan motor that you’re using only has three leads coming off of it, this will be the wiring setup that you’ll be using. You’re going to wire the black lead back to where it was previously wired. This will likely be back to your contactor. You’re going to wire the white lead to one set of terminals on your new capacitor. You’re going to need to wire a jumper from this set of terminals back to the other leg on your contactor. Finally, you’re going to wire the brown lead to the opposite set of terminals on your new run capacitor than the common lead.

Sum it all up:

There’s always a sense of fulfillment when completing a project yourself, but wiring a new condenser fan motor and run capacitor can be a bit tricky if you haven’t done it before. Safety is always the highest priority. Make sure the electrical supply to the condenser unit is disconnected before beginning any work. Use your multimeter to confirm the disconnection. If you’re not comfortable working with electricity, contact a local HVAC contractor and they will be more than happy to complete this task for you.

It’s very helpful to document the location of existing wire connections before removing the condenser fan motor or run capacitor. Use a camera to take pictures of the connections and reference the pictures when installing the new condenser fan motor and run capacitor.

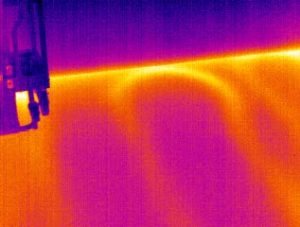

For a visual picture of typical wiring configurations, reference the following guide: HVAC Condenser Fan Motor Wiring Diagram.

Finally, this guide is intended to be used as a general overview of common condenser unit wiring schematics. Some condenser fan motors wire to a circuit board while others use proprietary plugs for their connectors. We strongly recommend referring back to your unit’s manual for proper wiring instructions.