DC Motors: Common Problems and Maintenance of Brushes

Brushes are vital to the efficiency and uptime of your DC and brushed AC motors because they are the electrical connection between the power source and the commutator. To effectively and efficiently transmit the electricity, brushes must have full, flat contact with the commutator at all times. Maintenance of brushes and commutators can help ensure a long lifetime of your DC motors.

What to look for when examining your brushes:

- Brush surface is smooth and shiny

- Brush surface is not chipped or cracked

- Brush shape conforms to commutator shape

- The brush is not too short (or worn down)

- Brush pigtail is in good condition

- Brush pigtail is securely fastened to the brush

If any of these conditions are not met, you should replace your brush. Generally, if the brush is worn down to 1/4th of its original length, it is time for replacement. If you need to replace your brushes make sure that the brush is the correct dimensions, type and grade for the motor. Typically you can find this information in your motor’s manual.

The 4 common problems found with commutators and brushes:

The most common issues found with DC motors includes: threading, grooving, copper drag, and flashover.

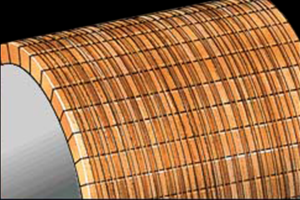

DC Motor Brush Problem: Threading

Threading results in fine lines on the surface of your commutator. The fine lines occur when copper is transferred from the commutator to the brushes. The copper becomes embedded in the surface of the brush and scratches the surface of the commutator. Threading can be caused by low brush pressure, contamination, or using the wrong type of brush. If there is evidence of threading, you must clean the commutator, clean or replace the brushes, and install the brushes with the proper tension.

DC Brush Threading

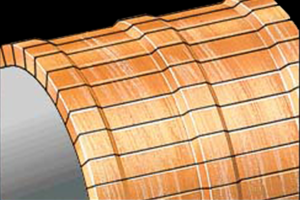

DC Motor Brush Problem: Grooving

Grooving leaves a smooth, slotted area on your commutators. Common causes of grooving include using the wrong brush grade, a brush with impurities, or contamination. When grooving is present, examine the type of brush used for grade and contamination. Replace or clean the brushes as necessary.

DC Brush Grooving

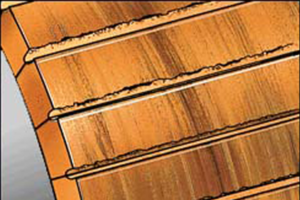

DC Motor Brush Problem: Copper Drag

Copper Drag is when copper particles are dragged to the segment edges of a commutator and is typically caused by brushes with too little tension, excessive vibration, or by an abrasive brush. It’s important to address copper drag immediately because the buildup of copper in the commutator segments can lead to a short circuit of the armature windings. The commutator should be cleaned of the copper flakes and the brushes should be examined for proper grade.

DC Brush Copper Drag

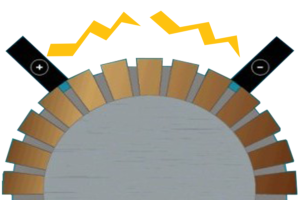

DC Motor Brush Problem: Flashover

Flashover is a short circuit between the brushes of a motor. The short circuit is caused by a buildup of dirt, copper particles, and debris between commutator segments. The segments are then shorted together resulting in arcing between the brushes. A flashover can be catastrophic to the motor and motor brushes. If a flashover occurs, the motor must be cleaned of all contaminates, the surface of the commutator cleaned or repaired, and the brushes will need to be inspected.

DC Brush Flashover

Because DC motors rely on brushes and many problems can arise from the brushes, maintenance should be conducted on a regular basis to check on the condition of your motors. By regularly examining your commutators, you can prolong the life of your DC motors by preventing any long term damaging problems or catastrophic failures. It is always smart to have spare brushes for your motors in case you need to replace your brushes due to wear and tear or contamination.

How are DC Motors and Commutators repaired?

If your DC motor has failed, it takes trained professionals to bring it back to OEM standards. To understand all of the steps that go into DC Motor and commutator repair, check out our guide here: Commutator Repair

How do you find replacement brushes?

Dreisilker understands the important of having replacement brushes ready for our customers, so we stock many common and uncommon brushes for your DC motors. Check out our brush stock here: Carbon Brushes

If you have any questions on the correct type of brushes you should be using, contact us today: