Accurate Machining on Electric Motors Makes a Big Difference

When it comes to electric motor repair, precision is everything. The smallest miscalculation in machining tolerances or assembly can lead to catastrophic failures, drastically shortening the life of a motor. We recently encountered a case that perfectly illustrates this point: a customer’s motor showed clear signs of incorrect bearing housing tolerance, leading to internal bearing preload. While this may seem like a minor oversight, the resulting damage was anything but small.

The Issue: Incorrect Bearing Housing Tolerance

In this particular case, the motor’s bearing housings were too tight, which caused an internal preload on the opposite drive-end bearing. Essentially, as the motor heated up during operation, the balls in the bearing were compressed beyond their intended load capacity. This additional friction significantly increased the heat within the bearing assembly, causing the inner race to thermally expand. Once the inner race expanded, it lost its secure grip on the shaft, becoming loose and leading to a chain reaction of failures.

A customer’s bearing that failed.

When the bearing loosened, it began spinning on the shaft, causing severe wear and damage. If left unchecked, this could have led to total failure, including rotor-to-stator contact, which would have resulted in an extremely costly repair or even complete motor replacement.

Understanding Internal Preload and Bearing Failure

Preloading in bearings is a critical factor that must be precisely calculated. It ensures that the rolling elements inside the bearing remain in constant contact with the raceways, minimizing vibration and improving stability. However, too much preload—caused in this case by an overly tight bearing housing—leads to excessive internal forces, which significantly accelerate wear and reduce bearing life.

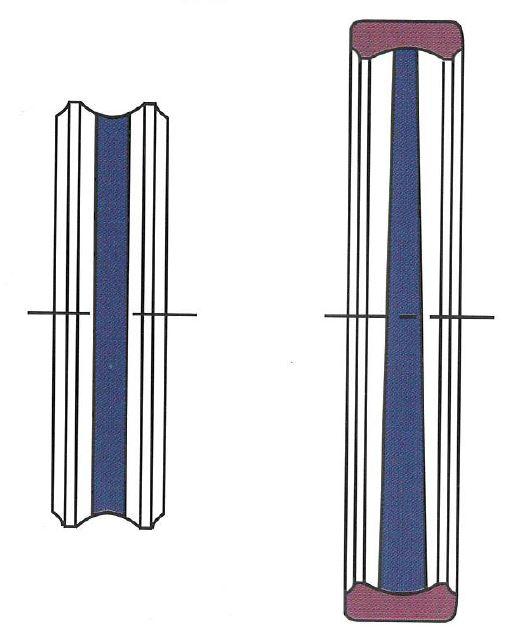

While it is difficult to capture the exact wear patterns caused by internal preloading in a photograph, we can illustrate this phenomenon with an example from the book Rolling Bearings Handbook and Troubleshooting Guide by Raymond A. Guyer, Jr. The illustration below helps visualize what happens when excessive preload creates excessive friction and wear on the bearing components:

The Value of Experience and Proper Machining

This real-world failure highlights the importance of expert machining and careful adherence to motor repair specifications. Our team of skilled technicians has an average of 16+ years of experience in electric motor repair. Their extensive knowledge, combined with strict quality standards, ensures that each motor we repair meets or exceeds industry specifications.

At Dreisilker Electric Motors, we leverage both our experience and engineering resources to diagnose issues like improper tolerances before they lead to failure. Our machining capabilities allow us to restore worn or damaged motor components to precise OEM specifications, preventing similar failures in the future.

The Cost of Failure: What Could Have Happened

Fortunately for our customer, they caught this issue before the rotor dropped onto the stator windings. Had they continued operating the motor in this compromised state, the excessive movement could have caused the rotor to grind against the windings, leading to a short circuit and irreversible damage. A winding failure would have left them with only two options: a much more expensive rewind or complete motor replacement—both of which would have resulted in costly downtime.

Preventing Future Failures with Precision Machining

To avoid issues like these, it is crucial to work with experts who understand the intricacies of electric motor repair. Proper machining techniques, adherence to manufacturer specifications, and thorough testing all play vital roles in ensuring a long-lasting motor repair. Whether it’s bearing fits, housing tolerances, or shaft repairs, every step of the process matters.

At Dreisilker, we take machining seriously because we know how much even the smallest detail can impact the performance and longevity of your motors. If you’d like to learn more about how our machining capabilities can extend the life of your equipment, check out our Machining Capabilities here.

By prioritizing precision and expertise, you can ensure that your electric motors remain reliable, efficient, and cost-effective for years to come.