Aegis Shaft Grounding Rings Protect your Motors and Bearings

Aegis Shaft Grounding Rings protects bearings and electric motors from damaging shaft voltages caused by variable frequency drives (VFDs). The voltages emitted by VFDs find their way to ground typically through the motor’s bearing. Some signs of these damaging currents include pitting, frosting, fluting and loss of bearing lubrication. Installing Aegis Shaft Grounding Rings to your motors can prevent bearing and motor failure caused by the shaft voltages.

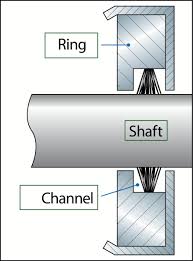

The Aegis Shaft Grounding Rings work by diverting the damaging voltages away from the bearings by sending it to ground through the motor frame. The rings are made of conductive microfibers that encircle the motor shaft and is installed on the drive end of the motor. For motors 100HP and higher, it is recommended to use an insulated bearing on the non-drive end with the Aegis Ring installed on the drive end.

Even though a motor may be rated inverter duty, you need to keep in mind that this does not mean that it comes with grounding rings preinstalled. If you need an inverter duty motor with grounding rings pre-installed, you will need to select the option for grounding rings. Most motors now have the option to come with grounding rings preinstalled. If you already have a motor in the field that needs protection, you can order an Aegis Shaft Grounding kit and install it on your motor.

There are different types of Aegis Rings that allow for installation on many applications. They are available in solid and split-ring designs, configured for NEMA and IEC motors, and include four mounting bracket styles and hardware. The different types of Aegis Rings can be found in our online store. If you need assistance finding the proper Aegis Rings for your application, we are able to help you source the rings.

Whenever you have a motor with grounding rings installed, you should add visually examining the Aegis Rings to your preventative maintenance checklist. Like most parts of a motor operation, grounding rings can be negatively affected by contamination. While checking your motors, inspect the rings for any sign of contamination that can cause ineffectivity of the ring. Aegis now offers a 2 year warranty against fluted bearings when you register your rings with Aegis.

Although the Aegis Shaft Ground Rings are a trustworthy solution to protect your motors, it is not the only solution to prevent damaging currents emitted by VFDs. Another solution that we highly recommend you utilize in conjunction with the Aegis Rings is CoolBlue Inductive Absorbers. CoolBlue are common mode chokes that are installed by placing the CoolBlue rings around the motor’s lead wires. To learn more about CoolBlue and its benefits, read “How CoolBlue Protects Your Motors and Bearings.”

If you are utilizing VFDs in your operations, you should consider protecting your bearings from damaging currents through the use of Aegis Shaft Grounding Rings and CoolBlue.

Leave a Reply

Want to join the discussion?Feel free to contribute!