Annual Electric Motor Checklist for Reliability

The New Year’s Resolution Guide to Your Motors

As we step into the new year, it’s the perfect time to reflect on the health and readiness of your operations. Electric motors and their ancillary parts are critical to keeping your business running smoothly, yet they’re often taken for granted until something goes wrong. This year, let’s resolve to take a proactive approach to maintaining these essential assets. Here are some key areas to review and optimize:

1. Do You Have the Right Spares on Hand?

Unexpected motor failures can lead to costly downtime. Having a spare motor ready can make all the difference in maintaining continuity. But how do you know when you need a spare? Our guide provides actionable insights to help you decide when investing in a spare is the right move for your operations.

In addition to keeping spare motors on hands, you may want to evaluate keeping spare parts on hand. These parts may include bearings, pulleys, or specialized parts like encoders. We keep a large stock of spare parts on hand for the hundreds of repairs that we conduct every month. Furthermore, we keep a stock of spare parts for different industries such as the Machine Tool and Printing industries. Make sure that you store these parts properly. Below we show a picture of rotors for servo motors that are wrapped to prevent dust and other contaminates from impacting the material.

2. Are You Storing Your Spare Motors Properly?

Having a spare motor is one thing, but improper storage can render it unusable when you need it most. Factors like temperature, humidity, and physical protection play a critical role in extending the life of stored motors. Learn how to store electric motors properly to ensure they’re ready for action. We keep a large inventory of spare motors at our headquarters for the Machine Tool and Printing industries. These motors are wrapped and stored in a humidity, climate controlled environment.

3. Is Your Preventative Maintenance Schedule Up to Date?

Preventative maintenance is the cornerstone of reliable motor performance. Regular inspections and servicing can identify issues before they become costly problems. This blog outlines the benefits of a consistent maintenance schedule and how it can save you time and money.

For facilities with DC motors, there are specific maintenance needs to consider, such as brush inspections and replacements. Check out our detailed guide to ensure your DC motors are in peak condition.

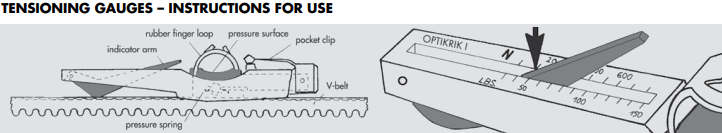

4. Are You Installing and Maintaining Belts Correctly?

Belt-driven systems are common in many operations, but improper tension or installation can lead to inefficiency, wear, and failure. Learn how improper belt tension affects your belt drive system and discover common belt problems that you can address proactively.

5. Have You Scheduled Infrared Analysis?

Infrared inspections are a highly effective way to identify potential issues with your equipment before they escalate. Many property insurance companies favor facilities that conduct regular infrared analysis, so it’s worth discussing this with your insurance provider. Explore the benefits of infrared inspection and consider scheduling this service as part of your annual maintenance plan.

Infrared Inspection

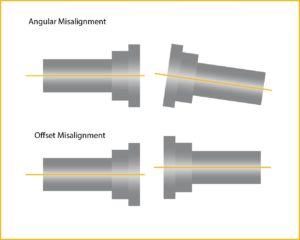

6. Are You Leveraging Vibration Analysis?

Vibration analysis can be a powerful tool in predicting motor maintenance needs or determining when a motor requires repair or replacement. Regular vibration checks can detect imbalances, misalignments, or bearing issues before they lead to significant downtime. We work with our customers to create tailored schedules—whether quarterly, monthly, or bi-annually—to suit their operational demands. Learn more about vibration analysis and how it can benefit your facility.

Start the Year Right

By addressing these key areas, you can set the foundation for a smoother, more efficient operation in the year ahead. Let’s make the new year where we prioritize reliability and efficiency for electric motors and their supporting systems. If you have any questions or need assistance with your motor maintenance strategy, don’t hesitate to reach out. Here’s to a successful and proactive year ahead!