Motor Starters: Types, Ratings, and Applications

Motor starters play a crucial role in industrial motor control by ensuring electric motors start, operate, and shut down safely. These devices serve three key functions:

- Control motor startup and shutdown to regulate power flow.

- Protect against overcurrent and overheating to prevent equipment damage.

- Enable automation and remote operation for improved efficiency.

Motor starters come in various configurations, each designed for specific applications, starting methods, and voltage requirements. This guide breaks down different starter types, ratings, and selection criteria to help you choose the best option for your needs.

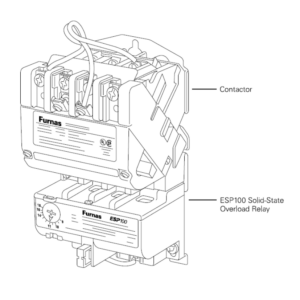

Siemens Furnas ESP100 Starter Courtesy of SIemens

What is a Motor Starter?

A motor starter is an electrical device that manages power delivery to a motor and provides overload protection. It is composed of:

- A contactor (switch) for power control

- An overload relay for motor protection

- A disconnect mechanism (in some cases) for safety isolation

Types of Motor Starters:

Full-Voltage (Direct-On-Line) Starters

A Direct-On-Line (DOL) starter offers the simplest and most widely used method for starting motors. It applies full-line voltage directly to the motor, providing a straightforward and cost-effective solution for small motors (typically under 10 HP).

DOL starters work best for non-sensitive loads that can handle high starting currents. However, they generate a significant inrush current—up to 600% of the motor’s full-load current. This surge puts stress on electrical systems and mechanical components, making DOL starters less suitable for high-inertia applications.

Despite this limitation, their simplicity and affordability make them a go-to choice for small pumps, compressors, and basic conveyor systems.

Reduced-Voltage Starters

Unlike DOL starters, reduced-voltage starters are designed to limit inrush current and voltage, preventing excessive electrical and mechanical stress on the motor during startup. These starters are commonly used for larger motors or in applications where reducing power disturbances is critical.

One of the most widely used reduced-voltage starters is the Star-Delta (Wye-Delta) Starter. This method initially starts the motor in a star (Y) configuration, which supplies a lower voltage and reduces starting torque. Once the motor reaches a sufficient speed, it transitions to a delta (Δ) configuration, providing full voltage and normal operation. This type of starter is commonly used in HVAC compressors, industrial fans, and water pumps, where a gradual increase in power helps protect the motor and electrical infrastructure.

Another type is the Autotransformer Starter, which utilizes a step-down transformer to supply reduced voltage to the motor during startup. This starter allows for different voltage tap settings—typically 50%, 65%, or 80% of full voltage—to suit various application requirements. The key advantage of autotransformer starters is that they provide higher starting torque compared to Star-Delta starters while still limiting inrush current. They are often found in high-torque applications such as blowers, large pumps, and industrial compressors.

The Part-Winding Starter is specifically designed for motors with two stator windings. Initially, only one winding is energized, allowing for a gentler startup. After a short delay, the second winding is connected, bringing the motor to full operational voltage. This method helps reduce electrical demand at startup while maintaining strong performance. Part-winding starters are commonly used in HVAC refrigeration compressors, industrial fans, and pump systems.

Another reduced-voltage method is the Primary Resistance Starter, which introduces series resistors into the motor circuit to restrict inrush current. As the motor accelerates, these resistors are gradually bypassed, allowing the motor to reach full speed. Although effective in limiting current, this method is less efficient due to energy loss in the resistors. It is primarily used in belt-driven conveyor systems, gear-driven equipment, and other applications where smooth acceleration is necessary.

Combination vs. Non-Combination Starters

Motor starters can be classified into combination and non-combination types, depending on how their protective components are integrated. A Combination Starter includes a contactor, overload relay, and disconnect switch within a single enclosure. This configuration ensures compliance with NEC safety regulations and simplifies installation by consolidating control and protection elements in one unit. Combination starters are preferred in applications requiring integrated safety measures and streamlined motor control.

In contrast, a Non-Combination Starter contains only the contactor and overload relay, requiring a separate disconnect switch to isolate the circuit. While this setup allows for greater customization, it necessitates additional wiring and panel space. Non-combination starters are often used in motor control centers (MCCs) where disconnects are installed separately for multiple motors.

Motor Starter Ratings: NEMA vs. IEC

NEMA Starter Ratings

NEMA (National Electrical Manufacturers Association) starters are rated by size and horsepower capacity. They are known for their heavy-duty construction and ability to handle harsh industrial environments.

| NEMA Size | Continuous Amp Rating | HP @ 230V | HP @ 460V |

|---|---|---|---|

| 00 | 9A | 1 HP | 2 HP |

| 0 | 18A | 3 HP | 5 HP |

| 1 | 27A | 7 HP | 10 HP |

| 2 | 45A | 15 HP | 25 HP |

| 3 | 90A | 30 HP | 50 HP |

| 4 | 135A | 50 HP | 100 HP |

| 5 | 270A | 100 HP | 200 HP |

IEC Starter Ratings

IEC (International Electrotechnical Commission) starters are compact, modular, and efficient. Instead of NEMA sizes, they use utilization categories, including:

- AC-1 – Non-inductive loads.

- AC-2 – Slip-ring motor starting.

- AC-3 – Standard motor switching.

- AC-4 – Plugging and reversing applications.

Selecting the Right Motor Starter

| Factor | Considerations |

|---|---|

| Motor Size (HP & Amps) | Larger motors need reduced-voltage starters. |

| Voltage Rating | Ensure compatibility with 230V, 460V, or 600V. |

| Starting Torque Needs | High-torque loads need autotransformer or part-winding starters. |

| NEMA vs. IEC Standards | NEMA for heavy-duty use, IEC for space-saving applications. |

| Duty Cycle & Frequency | High-cycling loads require AC-4 rated starters. |

Conclusion

Motor starters play a critical role in industrial motor control, ensuring smooth operation, overload protection, and longevity. Whether you need a DOL starter for a small pump or a soft starter for industrial automation, understanding their types, ratings, and applications is key.

Need help selecting a motor starter? Contact Dreisilker Electric Motors for expert recommendations.