Common Belt Problems: Keeping Your Belt Drive Systems Running Smoothly

Belts, along with electric motors, shafts, and pulleys, are a critical component of power transmission in belt drive systems. While belts require very little maintenance, improper belt tension, misalignment of pulleys, mishandling of belts, and environmental factors are common problems that can shorten the life of your belts and bring your system to a halt.

Improper Tension of V-Belts

If a belt is not tensioned properly, it will ride too loose or too tight on the pulley. A belt that’s too loose on a pulley will cause slippage, which leads to heat build up from friction. This heat will damage your rubber belts and cause the belts to crack and break. A belt that’s too tight can add stress to your bearings and cause your motor to over amp, leading to motor failure. Making sure that your belts are tensioned properly is simple and can help prevent the added costs associated with electric motor or belt failure.

Here are a few signs that a belt is improperly tensioned:

- Cracking of the belt

- Pieces broken off

- Hardened appearance

- The belt squeals during startup

- Pulleys wearing out prematurely

- Over amperage of your motor

- Worn out front motor bearing

We recommend the use of a tension gauge like Optikrik by Optibelt to ensure proper tension. To learn more about improper tension and how to check the tension of your belt, read our blog How Improper Belt Tension can Affect your Belt Drive System.

V-Belts that are not tensioned properly:

Misalignment of Pulleys and how they impact your V-Belts

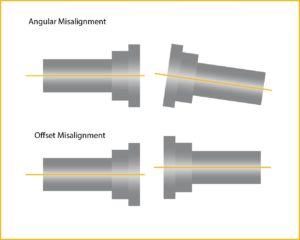

Pulleys need to be aligned properly in order to prevent premature wear on belts and pulleys, increased vibration and drive instability. The following are the types of misalignment:

- Parallel: A pulley is outside the plane of the other pulley, but their shafts are parallel

- Angular: The pulleys are in the same drive system plane, but their shafts are not parallel.

- Combination: Pulleys can be misaligned with a combination of Parallel and Angular misalignment.

Always check the alignment of pulleys after tensioning the belt because sometimes during tensioning, the pulleys can move. To check the alignment of pulleys, you can use a laser alignment tool or a machine straight edge. Check out our blog on our how experience field service technicians use Laser Alignment to align pulleys: How to: Laser Shaft Alignment

Types of Misalignment:

Mishandling of V-Belts

Mishandling of belts can also lead to premature belt failure. Here are a few things to keep in mind when using belts:

- Belts should never be forced onto pulleys. If the belt is too tight to put on the drive system, remove one of the pulleys and then install the belt.

- When working with belts, never twist, bend or crimp the belts.

- When replacing belts on drive systems, use matching sets. It is a good practice to replace all belts on a belt drive, even if a belt looks in good condition.

Environmental Factors the impact your V-Belts

Even though belts are durable, there are still some environmental factors that affect them:

- If possible, keep belts in an environment less than 80 degrees Fahrenheit.

- Do not allow grease, oil, lubricants and etc to contaminate the belts.

- When changing out a belt, it is a good practice to clean the pulley grooves. Any dust or debris can negatively affect the belt and the pulley.

- Harsh environments such as high humidity, extreme temperatures and direct exposure to sunlight can cause premature failure.

Understanding the common issues found with belts and knowing how to prevent them, can help improve the up-time and reliability of your belt drive applications.

How to find a replacement V-Belt:

Leave a Reply

Want to join the discussion?Feel free to contribute!