Environmental Impact of the MotorSafe Electric Motor Repair Process

The MotorSafe Electric Motor Repair process plays a important role in promoting environmental sustainability and aiding companies in achieving their green goals. By focusing on efficiency and precision, our repair method focuses on a motor’s efficiency, optimizes motor lifespans, and enhances resource efficiency. As a result, MotorSafe Repair ensures the efficiencies of motors to optimize their energy consumption for critical operations. The MotorSafe Repair process can have a positive impact on the environment and help companies meet their sustainability goals in several ways:

Focus on Energy Consumption: The biggest impact an electric motor repair service center can have on a motor’s energy consumption is within the rewinding process. If a motor is found to need a rewind, it is important to understand how the windings are stripped. With our MotorSafe Repair Method, we measure a motor’s core loss before and after stripping. The core loss testing process checks for overheating, damage, and hot spots within the motor’s core. A motor that does not pass our core loss testing would not run efficiently, leading to possible overheating and a shortened life span. In this case, we would recommend replacement of the core (when possible) to avoid efficiency issues. After the core loss testing, we proceed with our MotorSafe Stripping Method which safely removes the coils from the motor – ensuring no further degradation to the motor’s core. In contrast to MotorSafe Stripping, the industry standard Burnout Incineration method (used by other electric motor repair facilities) can introduce electric motors to considerable, damaging heat. At Dreisilker, we always conduct the core loss test before and after the stripping process to confirm the motor’s core condition.

To learn more about the environmental impact of electric motor repair, read our study: Burnout Oven vs MotorSafe Repair

Testing a motor’s core.

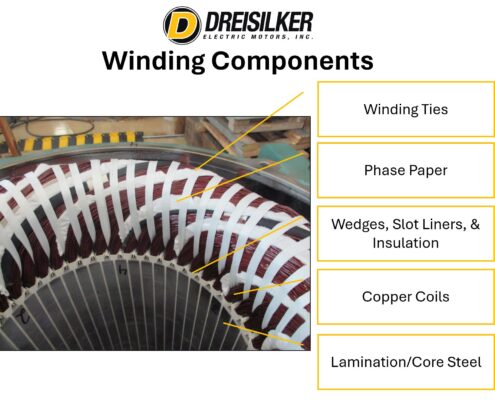

Materials Used in the Repair: A critical part of a motor’s efficiency includes the materials used in the repair. There are many standards imposed by the National Electrical Manufacturers Association (NEMA) that impacts how motors are manufactured and how we repair our motors. The standards created by NEMA can dictated the type of copper wire, the insulation paper, the varnish, and etc. Our skilled rewinding technicians examine the motor we received, its nameplate, and its data packs to understand what replacement material we need to use throughout the repair.

We use Class H wire in our rewinding method and we carry Class N rated varnish, which allows the windings to withstand higher temperatures. Furthermore, the varnish is hermetic rated which impacts the operations of compressor motors.

Taking Extra Steps: There are many ways how taking extra steps during a repair can impact the efficiency and longevity of motors. For example:

- Crease and Cuffing: We use high quality slot paper that we crease and cuff for every slot. The cuff allows for mechanical rigidity of the windings, limiting vibration and increasing reliability. Read more here: The Basic Steps of an Electric Motor Rewind

- Tying down slots: We tie down every slot during a rewind which helps aid the cuffs for mechanical rigidity. Most repair facilities and ever manufacturers take a short cut and tie down every other slot to save time. Read more here: The Basic Steps of an Electric Motor Rewind

- Proper cool down: During the double dip and bake varnish process, we let the windings cool after curing in the oven before dipping them again in varnish. Allowing the motor to cool ensures the varnish adheres properly to the windings. If the motor is too hot, the varnish will become too viscous and run off the windings more easily. Read more here: 4 Types of Motor Winding Insulation Methods

Dreisilker’s rewind for a random wound motor.

Recycling: Dreisilker works with certified partners in order to recycle and dispose of materials from the electric motor repair process. Throughout a typical motor repair, it is possible for us to need to replace many components of the motor including bearings, coils, end bells, shafts and more. Our technicians are trained on how to sort and recycle these different types of materials. Sorting different resources enables us to collaborate with our partners to properly recycle materials, ensuring they can be reused. Like many other industries, we use solvents and chemicals within the repair process. We partner with chemical disposal companies so that we are limiting the environmental impact of these used chemicals.

In conclusion, the MotorSafe Electric Motor Repair process acknowledges the need for environmental sustainability and supports companies in meeting their green goals. By emphasizing energy efficiency, precision in repair techniques, and the use of high-quality materials, MotorSafe enhances motor performance and longevity. Our meticulous approach to rewinding, repairing, and material selection ensures motors operate optimally, reducing energy consumption and minimizing environmental impact. Additionally, our commitment to responsible recycling and disposal practices underscores our dedication to sustainability. By adopting the MotorSafe Repair method, companies can achieve greater operational efficiency while aligning with their environmental and sustainability objectives.