How Improper Belt Tension can Affect your Belt Drive System

V-belts are an important part of a power transmission system. They allow for the transfer of energy from one source to another. While belts require little maintenance, they can greatly be impacted by improper belt tension. As discussed in our Common Belt Problems blog, improper belt tension is a leading cause of issues in your belt drive systems.

There are two scenarios for improper belt tensioning: too tight and too loose.

When a v-belt is too tight:

If a belt is too tight in a system, it can add stress to your bearings. The added stress to bearings can result into over amperage of your motor and potential motor failure.

When a v-belt is too loose:

When a v-belt sits loose on a pulley, the belt can slip while in motion and cause extra friction. The additional friction can result in a buildup of heat on the belt and the pulley. The excess heat can cause premature damage to your belts.

Some symptoms of improper tensioning include:

- Cracking of the belt

- Pieces breaking off

- Hardened appearance

- Squealing during startup

- Over amperage of your motor

- Pulleys wearing out prematurely

- Worn our front motor bearing

How to check the tension of your v-belt:

If you notice any of these issues while examining your drive symptoms, or if you’re installing a new v-belt, we recommend that you test the tension of your v-belts. Follow this step by step process to check your tensioning:

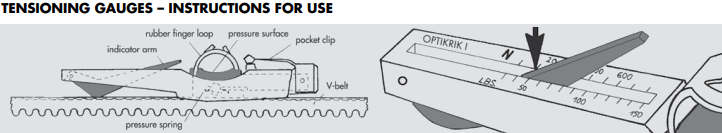

- After installation of your belt, take your Optikrik tension gauge and insert your finger underneath the rubber strap.

- Next, place the Optikrik at the center of the belt; lay it flat and parallel with the belt edge and then press slowly and straight down on the belt.

- Continue to press down with the Optikrik until you hear a click.

- After the click, you can now read the belt tension by looking at the cross point of the scale.

- Next, compare the measured tension to what the tension of the belt should be by using Optibelt’s formula posted below.

If the tension is correct, you are good to go. If the tension is off, make some adjustments and continue to test your tension in order to ensure the reliability and up-time of your belt drive system.

Leave a Reply

Want to join the discussion?Feel free to contribute!