Infrared Inspections and How They Can Prevent Costly Downtime

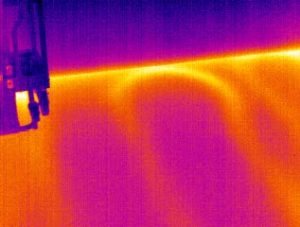

Infrared Thermography is a reliable method used for predictive maintenance and troubleshooting of electrical systems. During an Infrared Inspection, a trained infrared thermographer uses a high quality infrared camera to detect heat signals. The thermographer then analyzes the pictures to look for potential issues or faults.

For a typical annual inspection, the thermographer evaluates the customer’s motor control center and circuit breakers. The panels are removed by the customer and the components are scanned with the camera. This will allow the technician to locate any loose wire connections and also find any signs of component failure. Once the data is collected, a report is created with images of the system, issues that need to be addressed, and possible corrective actions.

Some of the problems the thermographer looks for in, motors, motor control centers and circuit breakers include:

- Hotspots

- Operational Temperatures

- Cooling Problems

- Overload Conditions

- Loose Connections

- Frayed Wires/Conductors

- Improperly Sized Wires

- Contaminated Connections

- Load Imbalance

- Faulty Components

There is no downtime required during an Infrared inspection, rather we ask that our customer’s system is running at or above 40% load. Evaluating the system when it is running at its typical load allows us to fully and accurately analyze the electrical system. After the inspection, we make recommendations on any corrections needed so that system failure can be prevented. If there are faults found upon inspection and the customer takes corrective measures, catastrophic system failures can be prevented.

We recommend an Infrared Thermography inspection for your critical electrical components at least twice a year. However, an annual inspection can still be beneficial. Keep in mind that some buildings are required to have yearly inspections as part of their insurance requirements.

Below are a few situations we’ve experienced during Infrared Inspections:

- Our thermographer was inspecting a control panel when he found a terminal that read at 200 degrees celsius. After informing the customer of the issue, the customer immediately shut down the operation so they could address the problem right away and prevent a possible fire.

- A motor winding was stripped using the burnout oven stripping method. Using an infrared camera, multiple hotspots were found showing temperatures that would destroy the motor if rewound and put back into service. The lamination stack had to be replaced prior to rewinding the motor to prevent premature failure.

- Floor heaters in an industrial garage were hardened into the concrete floor. The owner wanted to rework the floor without damaging the heaters. The infrared technician was able to find mark where the heaters were located and verify they were working at the correct settings.

If you would like to schedule a preventative Infrared Inspection, call us today.

Leave a Reply

Want to join the discussion?Feel free to contribute!