Infrared Inspection

What is an Infrared Inspection?

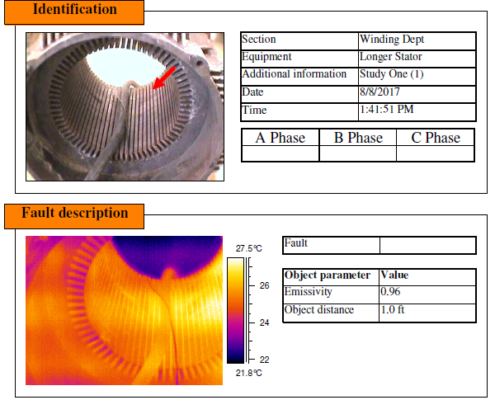

Infrared thermography is a non-destructive and non-intrusive testing process used as predictive maintenance inspection technique to detail abnormal heat patterns in machines.

What to Expect During an Infrared Inspection

During an Infrared inspection, our well-trained and experienced technicians skillfully use a thermal imaging device which emits thermal infrared energy. This device will detect hotspots, heat loss, leaks, insulation problems and other abnormalities in machines which are undetectable by the human eye. When those abnormalities are present it is usually an early indicator that there are corroded electrical connections, damaged components and equipment failure will likely occur.

Some of the problems the thermographer looks for in, motors, motor control centers and circuit breakers include:

- Hotspots

- Operational Temperatures

- Cooling Problems

- Overload Conditions

- Loose Connections

- Frayed Wires/Conductors

- Improperly Sized Wires

- Contaminated Connections

- Load Imbalance

- Faulty Components

Infrared Testing on a Motor