Armature Repair

Complete Armature Repair Services

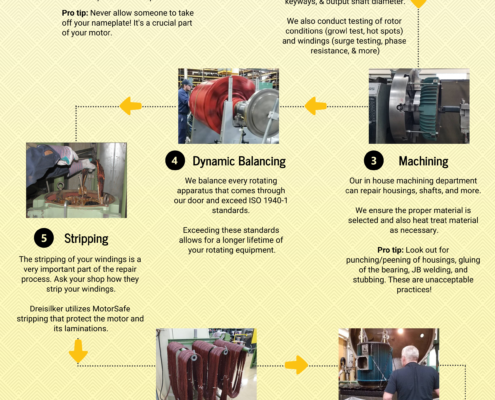

An armature is made up of many different parts which requires specialized experience in order to repair properly. The armature contains a winding, commutator bar, and an armature shaft. Below, we will walk you through how we take special care throughout the repair process. Our overview will cover how we rewind armatures, how we repair the commutator, cover machine work for armatures, and the importance of balancing armatures.