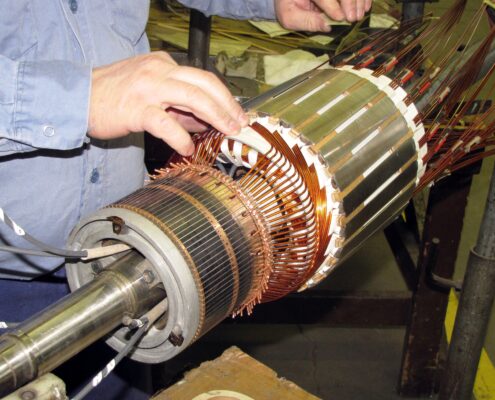

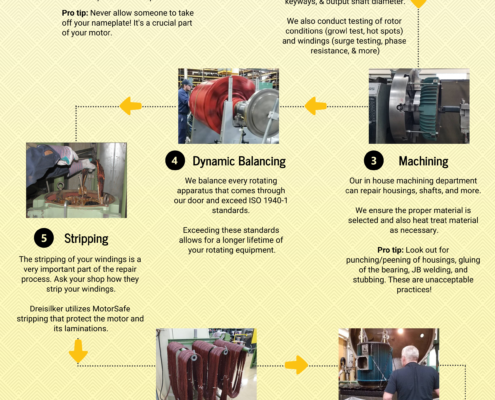

Armature Rewinding

As armature rewinding is a critical part of the repair process of an electric motor, Dreisilker takes pride in its armature rewinding services. We have been rewinding armatures for decades and our experienced winders use the best quality materials in order to repair armatures for our customers. Our armature rewinding services are precise and accurate, ensuring that your armature is repaired correctly the first time. Contact Dreisilker today for all of your armature rewinding needs. Learn about how we restore commutators here: Commutator Repair

Please note that we are not able to wind small power tools, vacuum blowers, automotive 6 or 12v, lift trucks 12, 24,36, 48v or golf cart armatures.