Impact of Electric Motor Repair on Efficiency

Repair Process Steps that Impact Electric Motor Efficiency

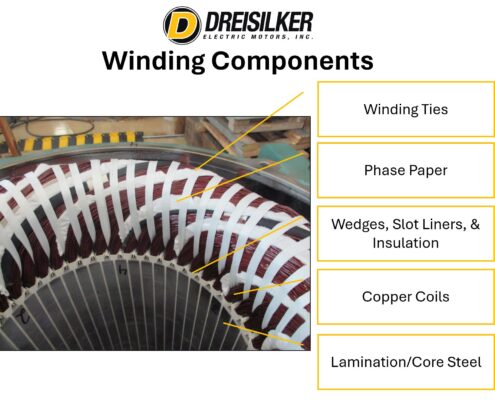

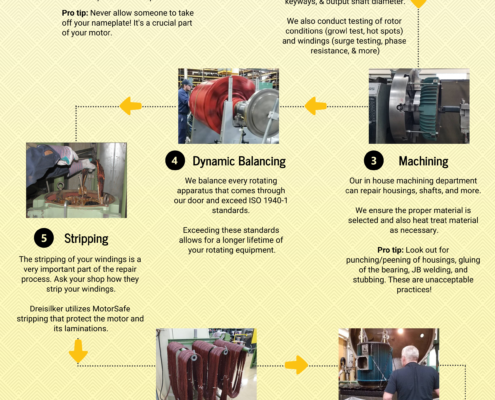

The repair process of electric motors involves several critical steps that can significantly impact their efficiency and overall performance. Each phase, from disassembly and inspection to rewinding and reassembly, plays a vital role in determining the motor’s reliability and energy consumption. Key practices and processes that impact the motor’s efficiency and reliability include:

- Careful removal of windings

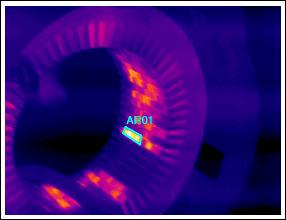

- Core loss testing

- Choice of winding and insulation materials

- Varnishing techniques

- Balancing

By adhering to recognized standards and employing best practices throughout the repair process, technicians can mitigate potential losses, ensure the lifespan of the motor, and ensure that it operates at peak efficiency, ultimately leading to reduced energy costs and improved performance in various applications.