Sustainable Electric Motor Repair

Considerations for Sustainability and Electric Motor Repair

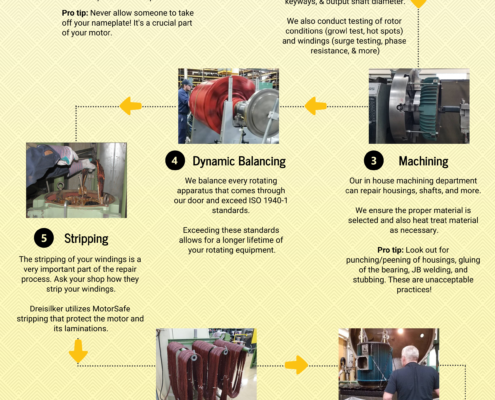

In today’s rapidly evolving industrial landscape, the pursuit of sustainability has become critical. As industries strive to minimize their environmental footprint and optimize resource utilization, the importance of sustainable practices in every aspect of operations cannot be overstated. Among the many components powering industrial processes, electric motors stand out as pivotal contributors to both energy consumption and environmental impact. Recognizing this, Dreisilker Electric Motors utilizes the Motor Safe Repair process, a comprehensive approach to motor repair aimed at the motors’ efficiency and reliability.

Inspecting a Rotor