Field Winding Failures for Printing Press Main Drive DC Motors

The reliability of main drive DC motors is paramount for printing presses. Yet, one persistent challenge that operators often grapple with is the occurrence of field winding failures. These failures not only disrupt production schedules but also pose significant maintenance headaches. Understanding the causes and implications surrounding field winding failures is crucial for maintaining uninterrupted workflow and ensuring the longevity of printing press machinery.

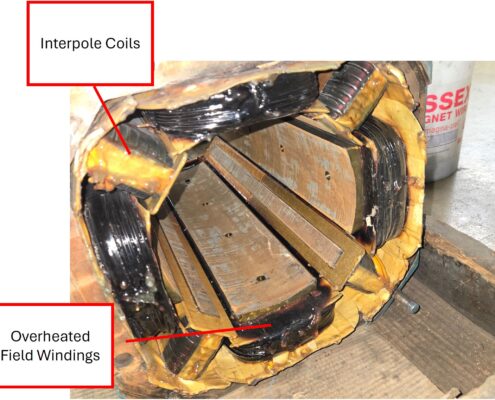

Overheated Field Windings in Main Drive DC Motors

Overheated field windings represent a prevalent issue encountered in printing press motors, often stemming from the continuous operation of these windings. In many printing press control systems, field windings are designed to remain energized consistently to ensure swift motor response and readiness for immediate use. However, this perpetual activation can lead to excessive heat buildup within the windings, eventually causing them to overheat. The resultant thermal stress gradually deteriorates the insulation and conductivity of the windings, compromising their efficiency and lifespan. Moreover, prolonged overheating can trigger thermal runaway, exacerbating the problem and potentially culminating in catastrophic motor failure. Effectively managing the temperature of field windings through strategic control schemes and periodic monitoring is indispensable for mitigating this common cause of printing press motor malfunctions.

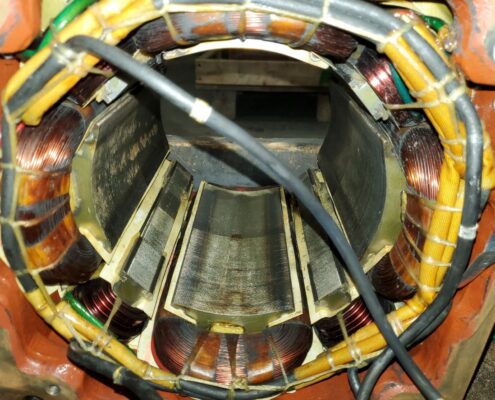

Field Coil Shorted to Ground in Main Drive DC Motors

Another prevalent issue afflicting printing press motors is field coil shorted to ground, which can significantly disrupt motor performance and reliability. This problem often arises due to insulation breakdown or physical damage to the field coil windings, leading to an unintended electrical connection between the coil and the motor’s grounded frame. When a field coil becomes shorted to ground, it creates an electrical pathway that diverts current away from its intended circuit, resulting in erratic motor behavior, decreased efficiency, and potential safety hazards. Moreover, the continuous flow of current through the shorted coil can exacerbate overheating, exacerbating the risk of further damage and escalating maintenance costs. Detecting and rectifying field coil shorts promptly through comprehensive insulation testing and meticulous visual inspections are essential steps in preserving the integrity and longevity of printing press motors.

Stator Windings

Field Coil Shorted to Ground.

Dreisilker’s Proactive Solutions for Printing Press Motors

At Dreisilker, we understand the importance of minimizing downtime for our customers, especially when it comes to critical equipment like printing press motors. To address this need, we offer a proactive solution by pre-winding stator, field, and interpole coils for certain models with commonly encountered motor configurations. By pre-winding these essential components, we significantly reduce emergency turnaround times, enabling our customers to swiftly replace faulty coils and restore motor functionality with minimal disruption to their operations. This proactive approach not only enhances operational efficiency but also demonstrates our commitment to delivering timely and effective solutions tailored to the specific needs of our customers. With Dreisilker’s pre-winding services, our customers can confidently navigate motor maintenance challenges and maintain seamless productivity in their printing press operations. Call us today to start your program.

Printing Press Repair Services

Our expertise goes further than just rewinds for printing press main drive motors. Check out our full capabilities here: Printing Press Motor Repair