Complete Machining Center

Dreisilker’s machine center has a staff of skilled machinists and precision equipment capabilities to provide high-value metal fabricating and tooling at outstanding quality– and with 24-hour emergency service available.

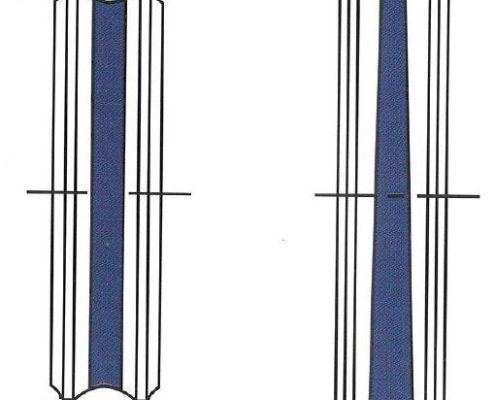

Our machinists have decades of cumulative experience with rebuilding motors, generators and other related equipment to match or exceed original specifications. If a part is no longer available, we can manufacture it from scratch, if necessary. Our inventory of various size lathes and specialized equipment allow the staff at our facility to build or rebuild whatever part or component you may need:

- Electroplating

- New motor shafts

- Motor related machine work

- Blower Shafts (solid and balloon)

- Fabricating adapter bases

- Special Parts

- Obsolete Parts

Dreisilker has the expert technicians and precision equipment in its machine shop to provide affordable, outstanding quality, and with 24-hour emergency service if needed. Our shop is comprised of highly skilled machinists with an average of 25 years machining experience along with a complement of trained support staff.

Various size lathes and specialized tooling equipment allow our facility to manufacture items with 15’ between centers and weighing up to 40,000 lbs., or to produce items smaller than a pencil lead.