Balloon Shaft and Solid Shaft Repair

Dreisilker has been creating and repairing custom balloon and solid shafts for over 30 years. Our machine shop specializes in accuracies up to a 0.0005 tolerance and uses higher quality steel than the OEM’s which significantly improves the shaft’s yield strength.

For shafts with an outside diameter of less than 4″, we can do any shaft length that you require. For shafts with an outside diameter of greater than 4″, we do shaft lengths up to 9′. We stock a variety of solid steel shaft sizes to meet our customer demands.

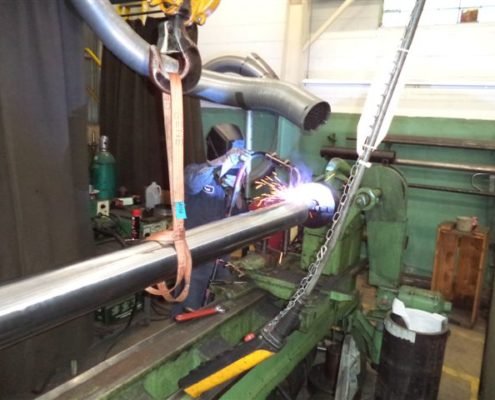

We can build custom solid shafts or rebuild with a drawing or sample. During balloon shaft repair, new shaft end plugs are welded to the balloon shaft. The repaired shaft is then tested for concentricity and runout. Shafts can be filled with foam by request. All shaft materials are stocked by Dreisilker which allows for rapid turnaround on your repair.

Dreisilker is also able to repair shafts using electroplating technology. Check out how we use this technology here: Electroplating Services

Dreisilker uses a higher quality steel (SAE-AISI 4140) than the OEM’s (SAE-AISI 1018) which significantly improves the shaft’s yield strength.

Dreisilker custom balloon shafts are dipped in chrome to help prevent corrosion and increase the shaft’s durability.

Dreisilker’s custom blower and balloon shafts are very competitively priced — resulting in a significant savings compared to the OEM prices.