Servo Motor Repair

Dreisilker understands that high precision and close tolerances are critical when working on all servo motor repairs. That’s why incoming Servo motor repairs are tested thoroughly and photographed before a formal quote is produced.

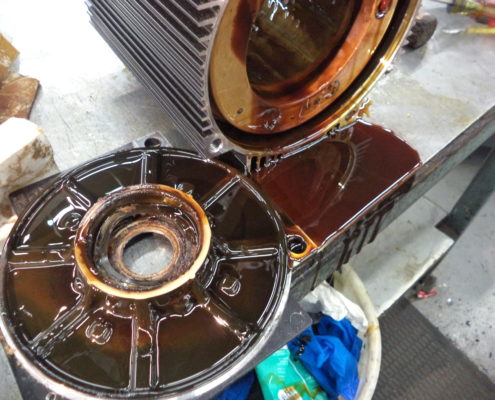

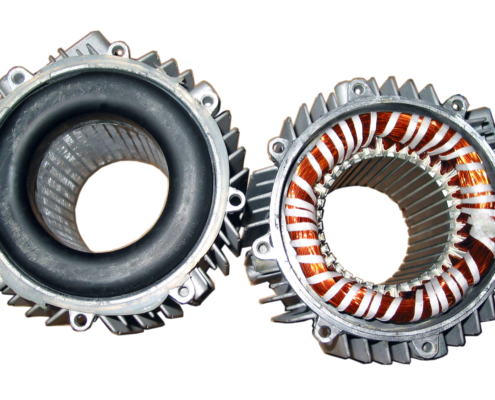

Dreisilker technicians run electrical tests and, if possible, test run the actual motor. Our technicians disassemble the motor and the motor’s bearings and journals are visually inspected. The motor’s stator is steam cleaned and sent to our winding department for testing. Dreisilker’s machining department measures the motor’s bearing housings and shaft journals. The work that we put into your motor before a repair even begins is what helps us return your motor back to it’s like-new condition.

Dreisilker has an extensive collection of Servo and Spindle motor drives, so we’re able to test feedback on most motors. Dreisilker inventories many replacement parts and we’re able to source most non-stocked parts from our suppliers.