Planning for Electric Motor Costs and Reliability

Set the Foundation for a Reliable Year

As you prepare your new year’s maintenance and capital budgets, one area that deserves extra attention is your electric motors. Motors power the systems that keep your facility running — from HVAC and pumps to production equipment. Yet too often, motor maintenance and replacement costs catch teams off guard.

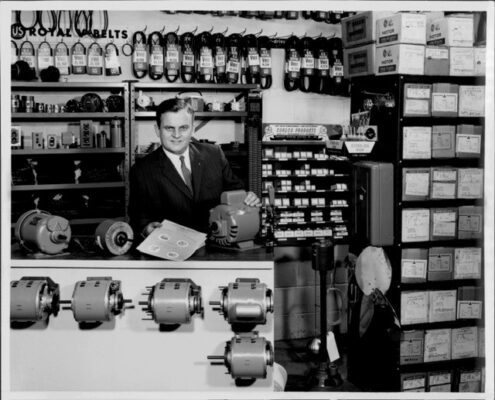

At Dreisilker, we’ve spent decades helping facilities make smart, proactive decisions about their motors. Whether it’s repairing, replacing, or upgrading systems for better reliability, a clear budget and preventive plan will save you both downtime and dollars.

In this blog, we outline key considerations to help you plan next year’s budget with confidence.

Understanding the True Cost of a Motor

The price of a motor is only part of the story. When you factor in labor, downtime, and lost production, the total cost of ownership can multiply quickly. For example, a 25-HP motor might cost a few thousand dollars, but an unexpected failure could cost far more in lost output and emergency repairs.

As Plant Services notes, “The real question isn’t ‘what does a new motor cost?’ but ‘what does a failed motor cost you per hour of downtime?’” That perspective shifts budgeting from simple cost comparison to reliability planning.

That’s why smart budgeting considers not just replacement costs, but also:

-

Scheduled maintenance and testing

-

Spare inventory for critical equipment

-

Condition monitoring services (vibration, infrared, or motor testing)

-

Reliability considerations, such as shaft grounding rings or CoolBlue inductive absorbers

When you look at motors through this lens, budgeting becomes less about reacting to breakdowns and more about keeping your operations steady, predictable, and profitable all year long.

Evaluate Repair vs. Replace Scenarios

When motors fail, knowing when to repair versus replace is key to budgeting accuracy.

Industry guidance suggests that if the repair cost exceeds roughly 60% of the cost of a new, high-efficiency motor, replacement may make more financial sense.

-

Repair is often best for large, custom, or legacy motors where replacement parts are costly or unavailable.

-

Replace when the motor is small, standard, or older and less efficient.

At Dreisilker, our motor experts help customers analyze both sides — factoring in age, efficiency, reliability, and long-term operating costs. To learn more about how we help our customers decide, read our article: When Do You Repair or Replace Your Electric Motor?

Know When to Keep a Spare Motor on Hand

Keeping a spare isn’t always necessary, but for certain applications, it’s the difference between hours and days of lost production.

Here are a few guidelines to help you budget wisely:

-

Consider a spare when the motor is critical to production, safety, or environmental control and has a long lead time for replacement.

-

Consider a spare if the motor is custom, obsolete, or specialty-rated, making replacement parts difficult to source quickly.

-

Rely on a replacement when the motor is a standard frame size that can be obtained within 24–48 hours.

-

When you do have a spare on hand, ensure that they are stored properly — in a clean, climate-controlled area, with shafts rotated periodically and windings checked for insulation resistance before installation.

Planning ahead for spares might feel like an added cost, but it’s really budgeting for uptime — protecting your operations from the far greater cost of unplanned downtime. To learn more, read our blog: When to have a Spare Electric Motor

Budget for Preventive Maintenance Services

Unexpected failures can throw even the most careful budgets off track. That’s why the most reliable facilities build Preventive Maintenance (PM) plans into their annual budgets. These plans turn unpredictable repair costs into planned, budgeted activities — helping you detect problems early and avoid expensive downtime.

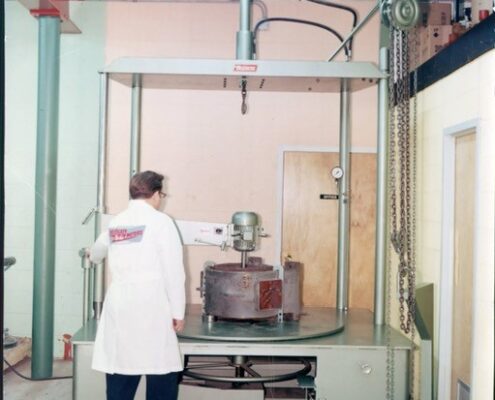

At Dreisilker, our PM programs are tailored to your equipment, schedule, and operational needs. Each partnership includes predictive technologies like infrared thermography and vibration analysis, along with detailed reports and trend data to support maintenance decisions.

Infrared Inspections

Infrared (IR) inspections use thermal imaging to identify heat patterns that point to hidden electrical or mechanical issues — such as loose connections, overloads, or failing bearings. By detecting these issues before they become failures, infrared analysis prevents unexpected shutdowns and improves safety.

Vibration Analysis

Vibration analysis measures the movement of motors and rotating equipment to catch early signs of imbalance, misalignment, looseness, or bearing wear. By trending data over time, our technicians can predict when components will need attention — allowing you to plan repairs during scheduled downtime instead of reacting to emergencies.

PM contracts not only make budgeting easier — they protect your investment and keep your motors performing at their best year after year.

Work With Your Motor Experts to Prevent Recurring Issues

Partnering with a trusted motor solutions provider should be part of your annual maintenance and capital plan. Building collaboration time into your budget ensures you’re not just fixing problems — you’re preventing them.

Preventive maintenance catches issues early, but only root-cause analysis stops them from happening again. By working with experts who understand both the electrical and mechanical sides of motor performance, you can uncover the true reasons behind failures — not just the symptoms.

At Dreisilker, our technicians and engineers work directly with customers to analyze failure patterns such as:

-

Bearing failure in VFD applications, caused by induced shaft voltage and circulating currents

-

Overheating or insulation breakdown due to poor ventilation or overloading

-

Misalignment and imbalance leading to vibration and premature wear

-

Contamination or moisture that damages windings and bearings

Through root-cause analysis, we identify the specific conditions that led to failure and recommend solutions to prevent them from happening again. In many cases, reliability upgrades — like installing CoolBlue inductive absorbers or shaft grounding rings — can significantly extend motor life in VFD-driven systems.

We realize this type of collaboration isn’t always a hard cost you can list in a budget. But it’s important to account for the soft costs — the time your team spends reviewing reports, discussing performance data, and planning improvements with us. That time investment pays dividends in fewer breakdowns, longer motor life, and a more predictable maintenance budget.

A trusted repair partner should do more than rebuild your motor — they should help you understand its environment, its stresses, and the steps you can take to make each repair stronger than the last. Working together on failure analysis and reliability improvements turns every repair into an opportunity for better performance and lower lifecycle costs.

The Bottom Line

Budgeting for electric motors isn’t just about numbers — it’s about reliability strategy. By planning for repairs, replacements, and proactive maintenance, you can reduce emergency expenses and keep your systems performing year-round.

“The only path to reducing reactive maintenance is to execute planned maintenance.” — Plant Services

Let’s work together to build yours.

Contact Dreisilker to review your 2026 maintenance and reliability plan.

We’ll help you estimate costs, prioritize upgrades, and schedule services that keep your motors running strong.